Parker is the global leader in motion and control technologies, providing precision-engineered solutions for a wide variety of mobile, industrial and aerospace markets. Parker can be found on and around everything that moves. They have unmatched breadth and depth of products that originate from a global leadership position in nine core Motion and Control technologies that include aerospace, climate control, electromechanical, filtration, fluid and gas handling, hydraulics, pneumatics, process control, sealing and shielding.

Power Generation Solutions

We offer a wide range of solutions for the power generation industry, encompassing various technologies and applications. Our product offerings include advanced solutions for natural gas combustion turbine applications, combined cycle systems and subsystems, fossil fuel and nuclear applications.

These product solutions are designed to enhance efficiency, reliability, and sustainability in power generation projects.

Fittings/Instrumentation

Parker Instrumentation tube fittings are designed to provide leak-free connections for aerospace, process, power and instrumentation applications. These single- and two-ferrule fitting designs are manufactured to the highest quality standards and are available in a broad range of sizes, materials and configurations.

Fittings-Hygienic

Parker fittings meet the special demands of the hygienic processing industry. Each component is built to precise manufacturing specifications and is designed to perform reliably in virtually every hygienic processing environment.

Tubing & Hose

Our instrumentation tubing, custom hose assemblies and tube support products ensure safe and efficient handling for all your fluid handling applications. We offer a wide range of industrial designs, as well as high-purity solutions for life science, food, beverage and laboratory applications.

Downstream Solutions

Process analytics require precise control of key parameters such as pressure, flow and temperature. Operational control requires providing a reliable sample to the analyzer and subsequent data for optimum system control. Key control areas for process analytical applications such as sample extraction, sample conditioning, and sample return to process or site removal systems, are optimized by use of Parker Instrumentation Products Division (IPD) analytical products.

Parker products are designed to meet the demanding requirements of critical process applications and are used for sam-ple isolation, stream selection, analyzer calibration, pressure regulation, flow and temperature control in liquid and gas systems.

COSE Series

The ChangeOver System (COSE) is a compact turnkey module that assists the operator with their total gas management. The COSE maintains a continuous gas delivery from two separate sources allowing for maximum cylinder gas usage from one source before automatically switching to the second source. The COSE lowers specialty gas costs by maximizing the consumption of gas from each cylinder. In addition, the gas cylinder bank(s) can be monitored remotely utilizing the optional pressure switches reducing the need for visual inspection by the operator.

Product Features:

- Fully enclosed to protect internal components

- Removable side panels for field maintenance

- Allows change out of depleted cylinder(s) while maintaining gas flow

- Especially suited for continuous on-stream analyzers

- Alarm sensor port for systems integration allowing user to monitor gas consumption

- Regulator design integrates positive upward and down ward stops which increases cycle life by preventing over stroking of the diaphragm

Quick Couplings

The Parker Hannifin Quick Coupling Division offers a full range of precision quick action couplings for use in the process, power and instrumentation fields. Parker quick couplings are built to stringent standards and meticulously tested for sealing integrity.

PTFE/PFA

Parker Partek and Parflex Divisions provide valves, fittings and tubing produced from only the finest fluoropolymers available. These fluoropolymers are used extensively in fluid-handling applications requiring resistance to aggressive chemicals and solvents. Products are also available meeting FDA and USP Class VI compliance.

Check Valves, Filters and Relief Valves

Parker has the most comprehensive range of instrumentation valves in today’s market. Their instrument valves are available in multiple configurations, end connection sizes and materials. The innovative design of these instrument valves enables them to perform in both high and low temperatures, pressures and with a wide variety of media. These valves can also perform efficiently in harsh operating conditions, including cryogenic, and are capable of meeting the specific needs of your system application.

Parker CB Series Check Valves – Coking Prevention

Problem:

When dual fuel combustion turbines run on fuel oil (diesel fuel), high temperatures can “cook” the fuel oil, leading to coke formations in the fuel lines and check valve locations. Once the check valve is “coked up” or sticky, it won’t operate properly, leading to uneven fuel distribution, hot spots, or failure to fire – problems that result in turbine trips or false starts.

Solution:

Parker check valves reduce coke deposits and buildup by using high-temperature sealing materials of “non-stick” carbongraphite and carbon-reinforced Teflon®, as well as a floating ball design inside the check valve. (Teflon® is the registered trademark of DuPont) Parker

Advantage:

Field proven, best-performing, and longestlasting air, water injection, and liquid fuel check valves in the industry. Designs for all OEM gas turbine applications.

For more detailed specifications visit Parker Here.

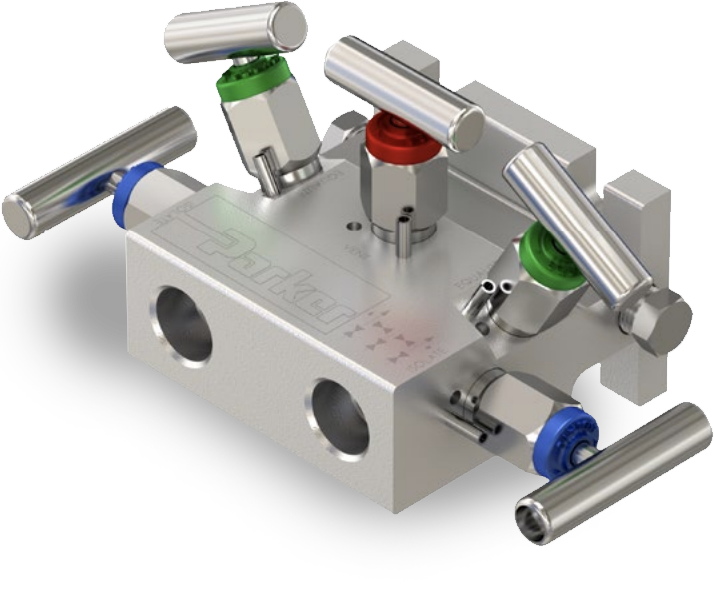

Global Instrumentation Manifolds

Parker’s Global Manifold range combines the manifold experience of three companies totalling over 100 years of manifold excellence. The ‘G Series’ of manifolds offers unrivaled technology, innovation, and availability.

Accessories

We offer a complete range of tube cutting, deburring, bending and assembly equipment for use in installing stainless steel and copper tubing systems. Parker’s stainless steel and aluminum sample cylinders provide safe containment for storage and transportation of both liquids and gases.

Contact a Dedicated Accutech Representative

Accutech has developed an extensive product offering through partnerships with industry leading manufacturers. With extensive experience in compressed air and fluid processing, count on us to meet your needs while improving your facility’s operation and efficiency.